LEAD Energy Storage Battery Manufacturing Solutions

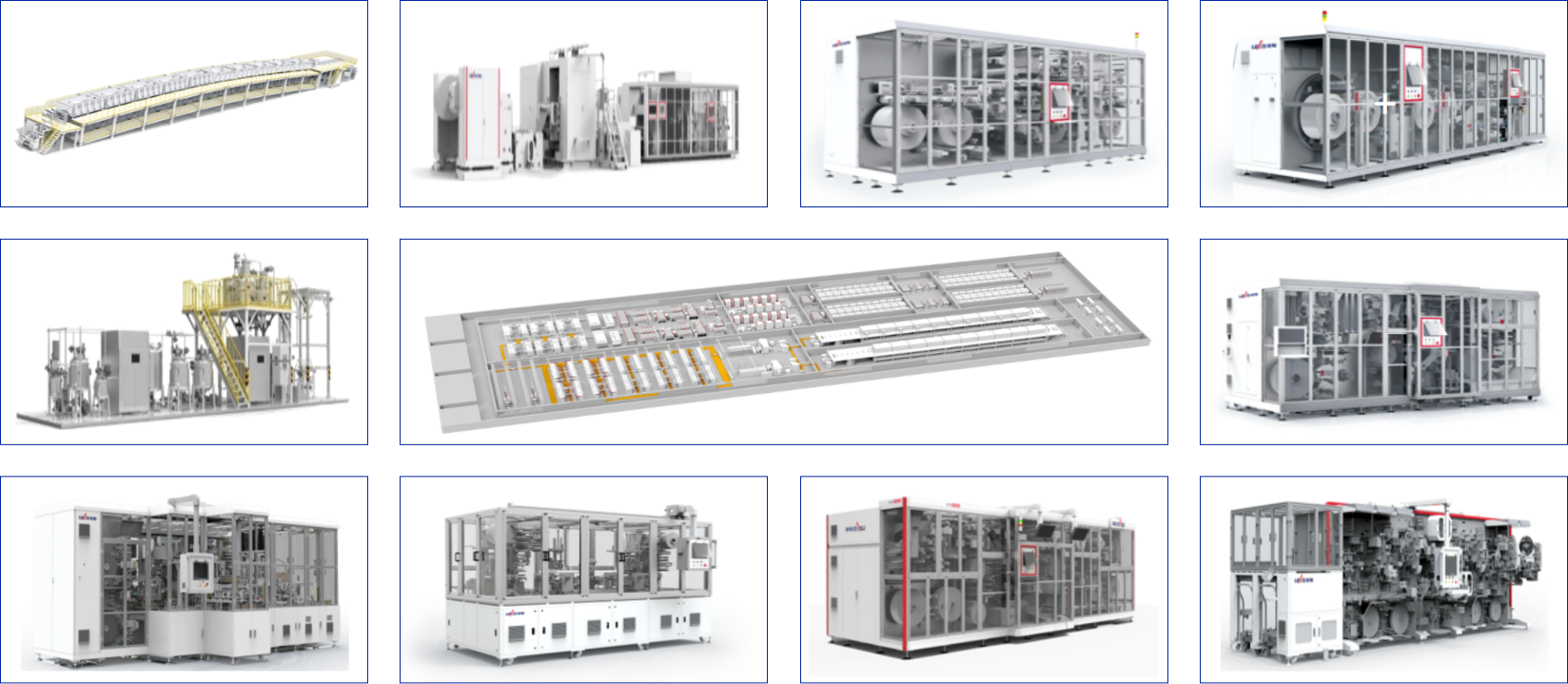

LEAD leads the energy storage batteries market, supplying LIB manufacturing turnkey solutions to top 3 clean energy service providers in the industry. Our lithium-ion battery manufacturing equipment—including cell manufacturing machines, lithium-ion battery assembly equipment, and testing systems—enhances efficiency while reducing costs per GWh.

The fully automated lithium-ion battery assembly line integrates smart MES and logistics, delivering higher capacity, lower energy consumption, and superior OEE. With advanced LIB equipment, LEAD provides a complete LIB manufacturing solution for cost-effective, high-yield production.

The fully automated lithium-ion battery assembly line integrates smart MES and logistics, delivering higher capacity, lower energy consumption, and superior OEE. With advanced LIB equipment, LEAD provides a complete LIB manufacturing solution for cost-effective, high-yield production.

Why Choose LEAD

Providing Energy Storage Turnkey Solutions

LEAD has completed 90+ orders for cell manufacturing whole lines, providing one-stop service.

Leading the Industry in Whole-line Availability

The line has excellent cycle time and yield rate.

Higher Efficiency

The energy storage battery single-line efficiency reaches 30PPM.

Lower Total Cost

LEAD’s LIB manufacturing equipment optimizes energy consumption and reduces downtime.

Advantages of LIB Manufacturing Turnkey Solution

LEAD LIB Manufacturing Turnkey Solution

Prismatic cells for energy storage batteries primarily adopt winding technology, with the 280Ah cell as the industry standard. The market is now shifting toward high-capacity cells, exemplified by our 530Ah winding cell (73*275*209 configuration, equivalent to a 100mm width increase over standard 280Ah cells).